Dynamic management of industrial maintenance processes

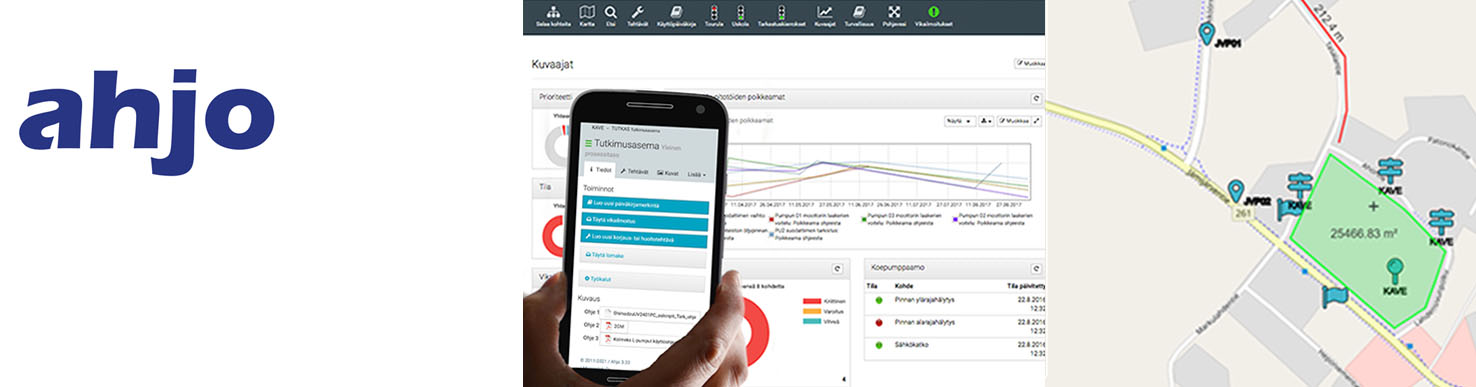

AHJO - maintenance management system

AHJO maintenance management system increases productivity and lowers costs. AHJO is a internet based software that enables dynamic management of industrial maintenance processes. Productivity of maintenance is increased through scheduling and delegating maintenance tasks. Machine down time is reduced by regular preventive maintenance checks, which leads to more savings in usage of spare parts and labor hours. Digitalizing your maintenance processes allows many individuals to access electronic manuals and repair procedures simultaneously as well as input information from many locations. These maintenance process improvements create a foundation for successful industrial operations.

AHJO CMMS software has features for every maintenance team member

Maintenance personnel

- Historical record of machine maintenance for quicker diagnosis of problems

- Easily available service history, equipment manuals, warranty information, and diagrams

- Ability to input information anyplace at any time in electronic format

- Information on availability and location of parts and materials

Maintenance supervisors

- Dashboard views of work status

- Scheduling of detailed inspection checklists by machine run time or calendar days

- Detailed instructions and procedures to ensure safety and effectiveness of work

- Ability to quickly train new staff in maintenance procedures

- Alerts and updates by email or text message

- Spare parts inventory management

- Capability to analyze long term maintenance trends and equipment issues

Power plant equipment room.

Operations managers

- Insight into long term labor and material costs in maintenance

- Analysis of staff productivity

- Fewer customer complaints due to less unscheduled downtime

Additional maintenance management features

- Maps with layers for graphic visualization of assets and data

- 3D views inside equipment areas with embedded information or links

- QR codes for quicker location of machine service history and input of data

- Addition of sensor data for IoT enabled preventive maintenance

LOGIN

LOGIN